The traditional stringer pallet configuration, comprised of top and bottom deck boards fastened to support boards, or ‘stringers’, running the entire length of the pallet, has been the most common type used in North America for many years. This design generally offers great value and performance for many domestic applications, but has some operational drawbacks by only being pallet jack accessible from the 2 of the 4 sides and can be incompatible with international logistics expectations.

Block pallets, consisting of multiple blocks and stringer boards tying the top and the bottom decks of the pallet together rather than a solid full length stringer, tend to be preferred by supply chains because they offer the significant advantage of true 4-way accessibility. Already dominant in Europe, Asia and most other parts of the world, the trend towards block pallet design is rapidly growing in North America and becoming the new standard for many forward thinking companies who recognize the performance advantages as well as those involved in global commerce who benefit from greater international compatibility and acceptance.

Skids are much less commonly found and are more limited in application than pallets. They can be constructed of either stringer or block design, but they differ from pallets primarily in that they have no bottom deck boards. This makes them less compatible with many operational, handling, storage and transportation systems, and more likely to lead to potential product damage or safety concerns with lateral collapse potential.

Achieve Objectives

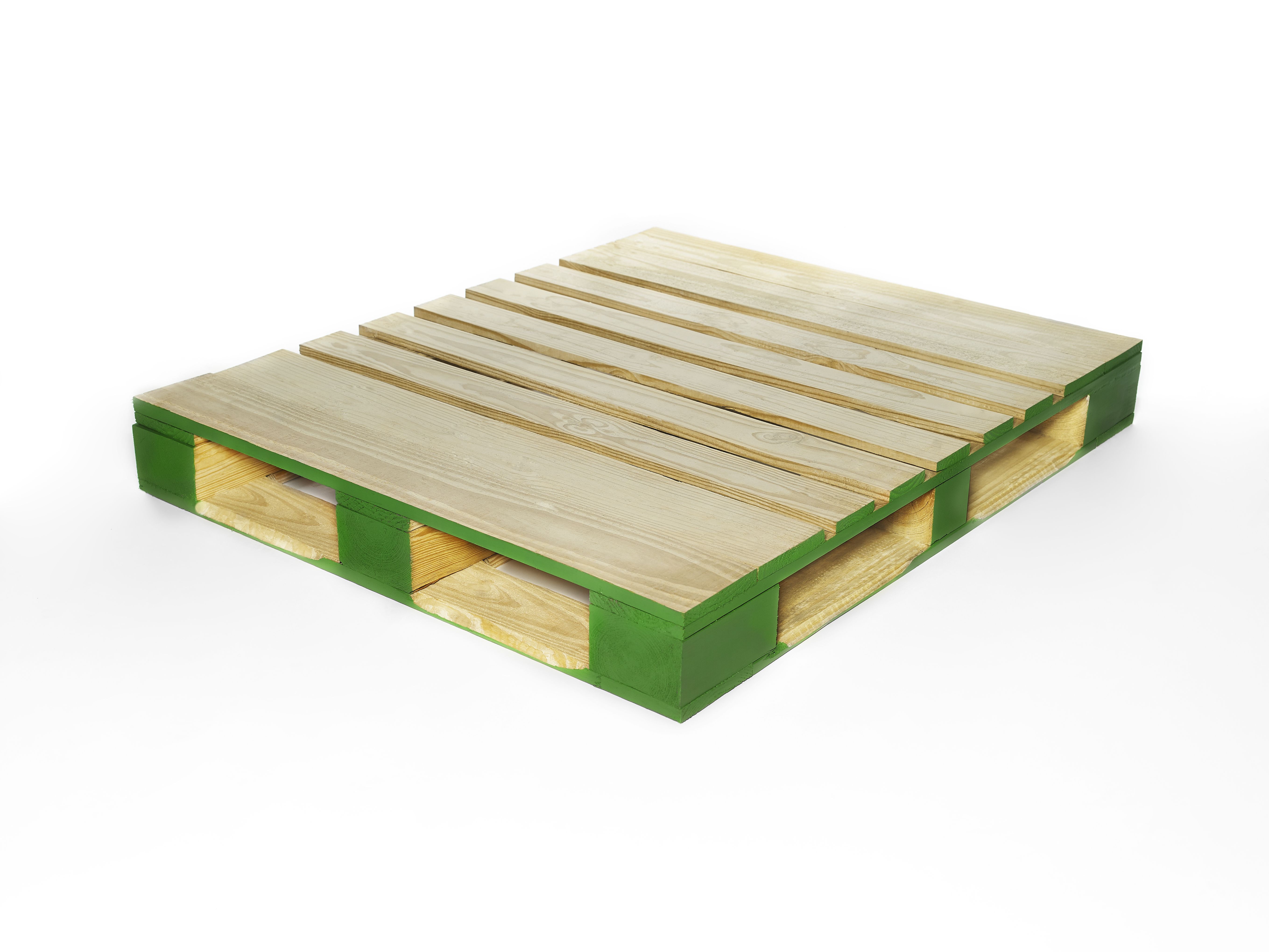

Every day, billions of pallets in thousands of different sizes and configurations are in active use around the world. While the diversity of products, packaging, handling, and logistical systems is vast, there is a common misconception that 'a pallet is just a pallet,' leading to insufficient consideration in the design and selection of this critical platform. This oversight often results in suboptimal outcomes, including product damage, operational inefficiencies, customer dissatisfaction, safety incidents, and unnecessary secondary costs. These issues can be easily avoided by recognizing the pallet as a vital component of the unit load and ensuring that its design is carefully tailored to the specific application, product, and packaging requirements. This approach guarantees optimal performance at the lowest overall cost.

Perfect Solution

Concerned about the cost? In fact, the most efficient way to minimize overall expenses and ensure top performance is to use the right tool for the job. Customizing the pallet design to align with your specific application and requirements doesn't increase costs — it optimizes them. By carefully matching the pallet to the exact needs of your product and logistical processes, we create an optimal balance between cost and performance, providing you with the confidence that the desired results will be achieved while also reducing unnecessary expenses. Investing in a tailored solution ensures that you achieve the best possible performance at the lowest total cost, delivering long-term value and reliability.

HELPFUL TIPS

Global Compatibility

As an alternative to a custom design tailored to your application you may find certain benefits, particularly for export applications, in utilizing an established and globally recognized standardized configuration delivering some consistency and compatibility within certain industries and applications.

The family of designs known as “CP Pallets” were originally developed by the Association of Plastics Manufacturers in Europe (APME) to harmonize industry standards. There are 9 unique configurations, and today their use has expanded broadly outside of Europe and to many other industries. The CP pallet designs ate quickly gaining prominence in North America, and are being adopted by many leading companies.

The GMA (Grocery Manufacturers Association) pallet, once the standard for North American grocery distribution, was designed as a durable 48" x 40" pallet to withstand supply chain demands. However, over time, cost-cutting measures have led to a decline in the quality and durability of GMA pallets, as the original specification has been watered down. As a result, the GMA pallet is now considered increasingly obsolete, with many businesses opting for custom or higher- quality pallets to meet the demands of modern logistics and reduce inefficiencies.

EPAL (European Pallet Association) pallets, commonly known as EUR pallets, are standardized wooden pallets widely used across Europe and beyond. They are designed according to strict specifications established by the European Pallet Association to ensure consistent quality, durability, and interoperability across various industries. Measuring 1200 mm x 800 mm, EPAL pallets are built to withstand heavy loads and repeated use, making them ideal for shipping, storage, and logistics. These pallets are also ISPM 15 compliant, meaning they are heat-treated to prevent the spread of pests, allowing for safe international transport.

Protective Solutions

For situations where pallets are subjected to particularly harsh environments, stored outdoors for extended periods in high-humidity or wet environments, sealed up in ocean containers for weeks at a time and subjected to condensation and lack of airflow, Neopal offers a variety of high performance protective treatment solutions which can offer significant protection against discoloration or mold growth on your pallets so you can rest easy and avoid unpleasant or costly surprises.