Enviroment

At Neopal, we are dedicated to creating products that not only meet the highest standards of performance and value but also contribute to a healthier planet for all. From the very beginning, we strive to implement the most effective and sustainable practices in our manufacturing processes. We believe that environmentally-friendly solutions are not just an addition to our offerings—they are integral to our mission of leading the industry with integrity and responsibility. By prioritizing sustainability, we ensure that our products not only excel in quality but also leave a positive impact on the environment for future generations.

In keeping with our unwavering commitment to environmental responsibility, Neopal has proudly built the world’s only LEED® (Leadership in Energy and Environmental Design) certified pallet manufacturing facility. Outfitted with ultra-efficient equipment and cutting-edge technology, our operations not only save energy but also significantly reduce our carbon footprint, all while enabling the production of precision-made, high-quality products. This pioneering approach exemplifies our dedication to sustainability, setting a new standard in the industry for eco-friendly manufacturing.

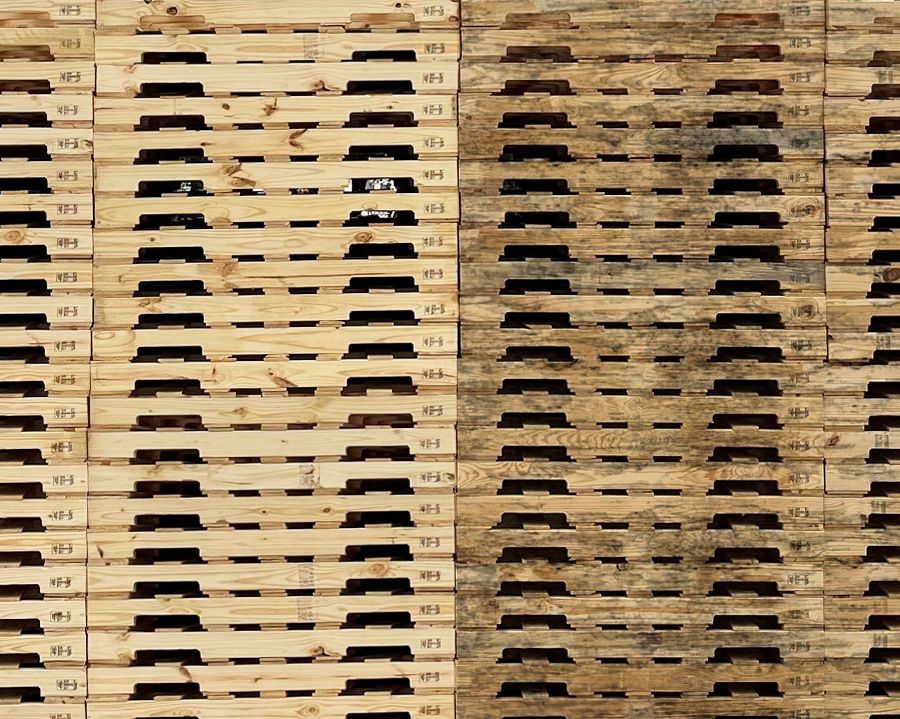

Renewable Kiln-Dried Southern Yellow Pine

Unlike the non-renewable species used often used in our industry, Neopal is committed to sustainability by exclusively using renewable Kiln-Dried Southern Yellow Pine. This rapidly renewable, durable, and versatile wood is the cornerstone of all our products. Southern Yellow Pine offers a superior strength-to-weight ratio, along with excellent resistance to mold, mildew, and pest infestation. The kiln-drying process further enhances the quality of our materials, preventing the shrinkage and warping often seen with ‘green’ lumber that contains high moisture levels. This process also strengthens the integrity of the nailing joints, ensuring greater stability, uniform sizing, and compliance with international phytosanitary standards.

Leaving Nothing to Waste

Beyond its renewability, our use of Kiln-Dried Southern Yellow Pine has enabled us to develop innovative processes that ensure zero waste in our manufacturing. Any components that are graded out or trimmed during production are repurposed through a multi-stage process, transforming them into alternative products such as particleboard and components and materials for different industries. Additionally, we are committed to recycling all corrugated packaging, metals, and plastics used across our office and manufacturing operations, further reinforcing our dedication to sustainability and environmental stewardship.

Energy Efficient Vehicles

Our fleet proudly features late model Volvo Trucks, renowned for their advanced safety features and environmental efficiencies. These state-of-the-art trucks are equipped with cutting-edge emissions control technology and fuel-efficient engines, ensuring reduced environmental impact and lower operational costs. Complemented by our lightweight aluminum deck Air Ride Trailers, our transportation system is optimized for both performance and sustainability. To further enhance efficiency, our vehicles are managed through a sophisticated computerized optimization system, which schedules deliveries with precision to minimize travel distances and delays. Each truck is fitted with a high-resolution touchscreen display integrated with our scheduling system, offering real-time GPS tracking, live traffic updates, and dynamic routing adjustments. This comprehensive approach maximizes transport efficiency while maintaining the highest standards of safety and environmental responsibility.

Mold Prevention

Offering optional mold preventative solutions for our industrial wood products not only enhances their durability and lifespan but also significantly benefits the environment. By preventing mold growth, our pallets and wood components maintain their structural integrity longer, reducing the need for replacement and thus minimizing waste. This protection safeguards the products transported on our pallets, preventing damage and rejection at client facilities or foreign ports, which in turn eliminates the need for additional work and transportation to resolve issues. By extending the useful life of our products and ensuring their reliability during use and transit, we contribute to a more sustainable supply chain and reduce the overall environmental impact.